EcoTipping Points

- How do they work?

- Leveraging vicious

cycles to virtuous - Ingredients for success

- Create your own

EcoTipping Points!

Stories by Region

- USA-Canada

- Latin America

- Europe

- Middle East

- South Asia

- Southeast Asia

- East Asia

- Africa

- Oceania-Australia

Stories by Topic

- Agriculture

- Business

- Education

- Energy

- Fisheries

- Forests

- Public Health

- Urban Ecosystems

- Water and Watersheds

Short Videos

- Saving a Coral Reef and Fishery (Apo Island, Philippines)

- Community Gardens Reverse Urban Decay (NYC, USA)

- Community Forests Reverse Tropical Deforestation (Thailand)

- Escaping the Pesticide Trap (India)

- Rainwater Harvesting and Groundwater Replenishment (Rajasthan, India)

How Success Works:

- Saving a Coral Reef and Fishery (Apo Island, Philippines)

- Community Gardens Reverse Urban Decay (NYC, USA)

- Community Forests Reverse Tropical Deforestation (Thailand)

- Escaping the Pesticide Trap (India)

- Rainwater Harvesting and Groundwater Replenishment (Rajasthan, India)

Human Ecology:

Principles underlying

EcoTipping Points

China - Biogas

- Author: Regina Gregory

- Posted: November 2010

- Quick Links: Biogas Technology • Economics • Popularization • Market Forces • Benefits • EcoTipping Points Analysis • Conclusion • References

Over 30 million households in China have biogas digesters that convert wastes into clean-burning fuel. Biogas accounts for about 1.2% of China’s total energy use, mostly replacing biomass and fossil fuels used for cooking in rural households. Biogas has 12 significant environmental and social benefits.

In China’s rural areas, most villages do not have electricity, and commercial fuels like kerosene and coal are expensive. Thus the rural population still relies heavily on biological sources of energy. Fuelwood and crop residues (mostly straw) account for 80% of rural household energy use and 54% of total rural energy use. The thermal efficiency (i.e., the amount of heat actually used) is only about 10% for traditional stoves, so a lot of fuel is required for such simple tasks as preparing food and tea (see Figure 1). This has serious environmental consequences, such as deforestation, reduced soil fertility, erosion, and even localized desertification. It also causes severe indoor air pollution, with resultant health effects such as upper respiratory infections and eye problems.

Figure 1. Cooking in rural China

Source: Smith (2007)

By just adding one simple step in the fuel cycle, biogas can alleviate many of these problems, and provide many other benefits as well. It is particularly well suited to China, where recycling and pig-rearing have long been common household activities.

Biogas Technology

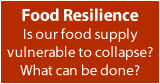

The basic biogas system involves an anaerobic digester (usually underground) with an inlet pipe, an outlet pipe, and a tube for the biogas (see Figure 2). The feedstock is a combination of plant and animal wastes, plus water. Crop residues as well as tree litter and weeds are suitable, as are manure from pigs, cows, chickens, and humans. It ferments in the digester tank to produce biogas, which contains 60-70% methane (CH4). The energy content is 22 gigajoules (GJ=1 billion joules) per m3, about the same as 0.5 liter of kerosene. The basic chemical reaction is: 2 C + 2 H2O » CH4 + CO2. The process occurs with the aid of bacteria, and is temperature sensitive (range is 8-60° C). Under ideal conditions, a 10 m3 digester can supply enough gas for cooking and lighting for a family of five. Biogas can also be used for fueling farm machinery and for power generation. Both the liquid sludge from the outlet pipe and the sediment at the bottom of the tank are very good fertilizers.

Figure 2. Basic biogas digester

Source: Kangmin and Ho (2006)

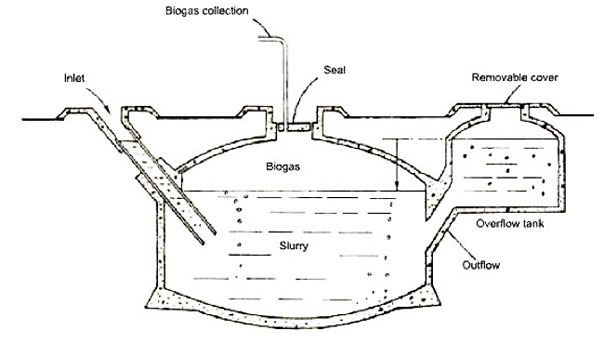

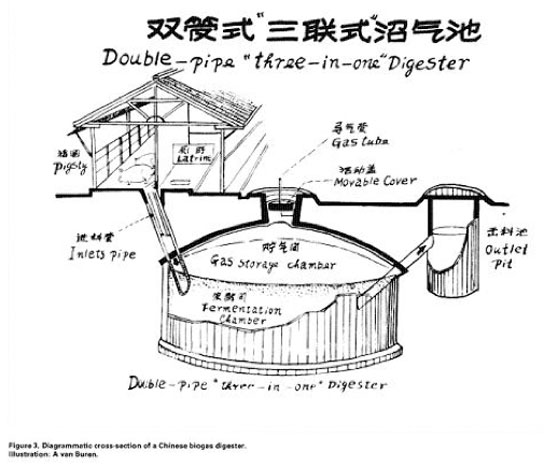

A slightly more elaborate model is the “three-in-one,” which includes a pigsty and latrine connected directly to the digester tank (see Figure 3). In warmer regions, the fertilizer can be applied on an orchard in the “pig-biogas-fruit” model. For colder regions, the “four-in-one” model with a greenhouse is recommended so the digester can “live through the winter.” (see Figure 4).

Figure 3. Three-in-one model

Source: van Buren (1980)

Figure 4. Four-in-one model

Source: Wang (2004)

Economics

Biogas digesters are generally constructed using local materials such as clay, sand, pebbles, and bricks, which makes them affordable and promotes local self-reliance (see Figure 5).

Figure 5. A 10 m3 brick digester under construction

Source: van Buren (1980)

Cost estimates vary widely, but Table 1 gives a recent and detailed representative example, including the costs of remodeling a kitchen, toilet, and pigpen (the “one new plant and three remodeling” model). The total cost is 3,534 yuan (equivalent to $US442), with 1,000 yuan coming from government subsidies. In the past, a portion of the costs and labor were contributed by the collective (commune). Now, micro-credit loans are available, with an interest subsidy financed by the local government. Farmers still contribute their own labor. Most analyses find that the costs can be recovered in 1-1.5 years from fuel savings, increased income, and extra time availability.

| Sub-project | Item | Cost (Yuan) | Money sources |

| 1. Biogas plant (8 m3) | Cement | 250 | Government subside (756 Yuan) |

| Transportation | 80 | ||

| Biogas facilities* | 256 | ||

| Mason cost | 170 | ||

| 130 | Farmer users (782 Yuan) |

||

| Slurry pump | 70 | ||

| Seal chemical material | 14 | ||

| Brick, Sand, Iron | 218 | ||

| Labor cost | 350 | ||

| Total | 1538 | ||

| 2. Kitchen remodeling | Mason cost | 15 | Government subsidy |

| Construction material | 147 | Farmer users | |

| Total | 162 | ||

| 3. Toilet remodeling | Mason cost | 15 | Government subsidy |

| Construction material | 250 | Farmer users | |

| Total | 265 | ||

| 4. Pen remodeling | Mason cost | 500 | Farmer users |

| Construction material | 855 | ||

| Cement & Iron | 214 | Government subsidy | |

| Total | 1569 | ||

| Total of all | 3534 | ||

*Biogas facilities include: a biogas stove, a lamp, a multi-function meter and pipe

The data is from Quizhou rural Energy Office

Table 1 Cost of construction of “one plant with three remodeling” in Changshun County, Guizhou in 2005

Source: Hu 2006

Popularization

According to Kangmin and Ho (2006), the first digestion plant to produce biogas from wastes was built in Bombay, India in 1859. By the end of the 19th century some simple biogas digesters appeared in the coastal areas of southern China. In 1932 Luo Guorui established the Chinese Guorui Biogas Company in Shanghai and published the first monograph on biogas, Chinese Guorui Biogas Digester Practical Lecture Notes. Around the same time, Prof. Zhou Peiyuan designed and built a digester for lighting in Jiangsu Province, and another was built in Zhejiang Province for generating electricity.

During the Great Leap Forward, in 1958-1960, Mao Zhedong declared that biogas should be popularized throughout the country (see Figure 6), but only a small number were built in some southern provinces. Technical support was insufficient for the movement to succeed.

Figure 6. Chairman Mao views a biogas stove demonstration, 1958

Source: Smith (2007)

It was actually the Sichuan provincial government that led the early popularization of biogas. In 1968, some farmers in Sichuan Province perfected the technology for constructing water pressure type digesters (i.e., ones that did not leak). Seeing the value of this technology—which provided fuel without decreasing the supply of organic fertilizer, as well as contributing to rural hygiene—the Sichuan government launched an extensive dissemination program in the early 1970s. One of its main features was technical training. According to van Buren (1980, p. 14), “After a one-month initial course at the provincial level, trainees return to their prefectures to serve as teachers. Their students then become teachers at the county level and extend the technology out to the communes, brigades, and teams.” A detailed construction manual was made widely available in 1976. While the basic technology is a water pressure digester, official policy encouraged initiative, experimentation, and creativity in locally available construction materials and feedstocks, as well as designs suited to local conditions (“adaptive R & D and incremental innovations,” in the words of Moulik (1985)). Sichuan became an example of the potential of biogas utilization for other provinces. Beginning in 1972 biogas conferences have been held in Sichuan, attended by representatives from all over the country.

The popularization program was based on the communes. Representatives from collectives visited successful biogas digester sites and decided on whether to try the technology. Then certain members were selected to receive training as technicians to oversee digester construction. Ordinary farmers could become certified, and then had extra income for being technicians. The number of household digesters within a collective grew gradually, and at 70% of households, a commune/brigade/team was considered “basically popularized.” According to Moulik (1985, p. 291),

The household benefits by saving on fuel costs, receiving free improved manure supply for the kitchen garden, gaining income from biomass input (particularly human and pig wastes) supplied to the biogas plant, and gaining income-earning opportunities for women due to less time spent cooking. The incentives for the collective are increased manure supplies and crop productivity, and lower commercial fuel costs through use of biogas for irrigation pumping and generation of electricity, as well as lower chemical fertilizer costs. The state gains because the biogas program lowers transport costs for energy supply (especially coal), conserves natural resources and promotes better sanitation.

The number of digesters in Sichuan grew to over 400,000 by mid-1975, and to 5 million in 1979. Nationwide, more than 7 million household digesters were constructed in 1973-1978, as well as about 30,000 larger-scale systems that served communes, distilleries and other industries with organic wastes, municipal sewage plants, hospitals and schools.

But the number of household digesters began to decline in 1979; it went from 7 million to about 4 million by 1983. This was due to far more existing digesters being abandoned than new ones being built. It may have had something to do with the new “responsibility system” introduced in 1978, which replaced the commune system with individual household leaseholds and different production incentives, along with a decline in large-scale rural construction efforts. But the decline is mainly attributed to technical problems. Apparently many digesters were constructed in a hurry with materials that were not very durable. Problems also arose with inappropriate feedstock, lack of maintenance and technical support services, and, in northern China, the cold winters. The government was forced to rethink its “adaptive R & D” approach and to establish better design standards. Ten research and development institutions were established to address the technical problems.

In 1980, the national government declared biogas the “principal alternative” to cope with the fuel crisis in rural villages. The National Methane Office devised a complicated index system for prioritizing different regions, based on local climatic conditions, firewood shortage, resource availability, and economic status. Special consideration was also given to “disease-prevention districts.” The categories were arranged as follows:

Climatic conditions

Number of months of the year with mean temperature of 10° C or higher

| I | 10-12 |

| II | 8-9 |

| III | 6-7 |

| IV | 4-5 |

| V | <4 |

Firewood shortage

Number of months of the year in which supply is less than 4,500 kcal of effective heat per person per day

| serious | >3 |

| normal | <3 |

Any county with over 60% serious is considered to be experiencing a serious shortage

Any county with 30-60% serious, or over 50% normal shortage has a normal shortage

Resource availability

Potential for methane production

| abundant | 1.5 m3 |

| normal | 0.8-1.5 m3 |

| deficient | <0.8 |

Economic status

Per capita annual income

| well off | <100 yuan |

| medium | 40-100 |

| poor | <40 |

These criteria are arranged into five categories, A through E, with A being a combination of serious firewood shortage, abundant resources, and high income, and E being combinations of no firewood shortage, deficient resources, and/or low income. Thus, each climatic region (I-V) has a set of five sub-regions (A-E).

Local governments were directed to include biogas as an important item in farm capital construction, and in the national plan a portion of the country’s cement resources was allocated for digesters. A State Leading Group on Biogas was established with representatives from various ministries, and day-to-day operations were delegated to the State Office of Biogas Utilization and Popularization. Biogas leading groups were set up in the provinces, municipalities, and autonomous regions, as well as in their subordinate counties and cities. Today the administrative network from the central government to the local government includes about 3,640 departments and agencies. “The state biogas promotion offices play a crucial role in arranging technician training programs, arranging for necessary materials, extending bank loans, sponsoring biogas research, and preparing technical literature” (Moulik 1985, p. 291). A subsidy of 1,000 yuan (about US$150) was offered for each digester.

The popularization program includes various forms of propaganda—manuals, cartoon books, posters, radio, film, and television, and more recently videos and DVDs—as well as demonstration projects. The dissemination of biogas coincides with China’s “constructing the new countryside” program. In the 1990s efforts focused on disseminating the southern “pig-biogas-fruit” model and the northern “four-in-one” model. Beginning in 2000, “one new plant and three remodeling” projects have been encouraged as well (see Table 1 above). Linzhou City in Henan Province is trying a new “three extension” approach for popularization and modernization: (1) develop middle and large scale plants; (2) use new mesophilic and thermophilic processes; (3) expand verified applications from just cooking to include lighting, home heating, water heating, and power generation.

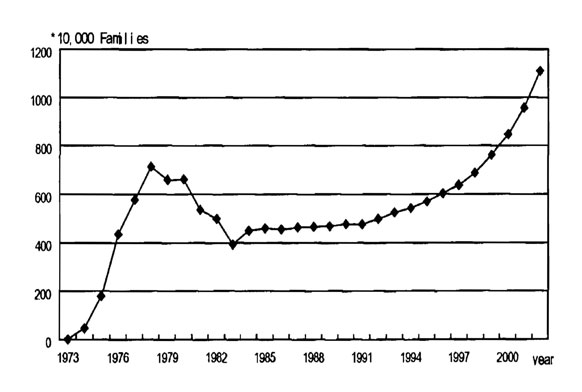

Figure 7 shows the number of household biogas digesters for the years 1973-2002. The number grew to over 11 million households.

Figure 7. Number of household biogas digesters in China, 1973-2002

Source: Wang (2004)

Official estimates for the number of household biogas digesters for 2004-2008 cited in the literature indicate a continued steady increase:

- 2004 - 15.4 million (Hu 2006)

- 2005 - 18 million (Lixin 2007)

- 2006 - 22 million (Gan and Yu 2008)

- 2007 - 26.5 million (USAID 2009)

- 2008 - 30.5 million (Tianren Trade News 2009a; People’s Daily 2009a)

Assuming each digester serves a household of five, one can say biogas serves almost 22% of China’s rural population. The digesters produced a total of 6.5 billion m3 of biogas in 2005, about 1.2% of China’s total rural household energy use.

Market Forces

China’s newest economic revolution—the shift to an export-focused, quasi-capitalist economy—has encouraged biogas popularization in several ways:

Larger livestock operations and more industry

Large livestock operations are growing in number. Each produces thousands of pounds of animal wastes daily. Large-scale digesters have been built which can provide gas to hundreds of households, or to generate electricity and/or heat in a power plant. China’s national plan for biogas, according to Junfeng (2007), includes 4,700 large-scale biogas projects on livestock farms and 1,600 using industrial organic effluents by 2010; 10,000 livestock farms and 6,000 industrial plants by 2020.

More foreign investment

In 2003 the Asian Development Bank and Chinese Ministry of Finance launched the Efficient Utilization of Agricultural Wastes Project, a $77 million project in Henan, Jangxi, Hubei and Shanxi Provinces. The aim is to build 17,500 household digesters as well as large-scale animal agribusinesses with digesters. Shanxi Province received $8.2 million in ADB loans, contributed $8.1 in matching funds, and received a $841,000 grant from the Global Environment Fund.

International environmental organizations have also become involved. The Nature Conservancy, for example, is helping to implement the United Nations Environment Programme’s China Rural Energy Enterprises Development (CREED) initiative. The initiative includes a GreenVillage Credit small loans program and promotes not only biogas digesters, but also solar water heaters, energy-efficient stoves, and rainwater collecting cisterns. So far the project has reached 420 villages in Yunnan Province, installing over 14,000 digesters, stoves, and solar water heaters.

Export of biogas technology

In 2007 a three-day Methane to Markets Partnership Expo in Beijing featured a broad array of innovative products and guests from around the world. The Qingdao Tianren Environment Co., Ltd. offers a permanent exhibition space and a comprehensive website for the sale and service of biogas plant equipment worldwide (see http://www.tianren.com).

The Chinese government plans to help countries along the Mekong River build 1,500 rural biogas tanks in 2009-2013. And Zhejing Province is helping its “sister state” of Pohnpei, Micronesia with four biogas projects including digesters and stoves. The first, providing biogas for the kitchen of OWHA Christian High School in Madolenihnw from the school’s piggery, was completed in April 2009.

The global carbon market

Under the Kyoto Protocol’s Clean Development Mechanism (CDM) as well as smaller facilities like the Carbon Catalog, developing countries “can make the rest of the world pay hard cash for not burning firewood to release carbon dioxide into the atmosphere,” in the words of Ho (n.d.). China is by far the biggest “host party” on the CDM registry. Its 665 projects are expected to produce an annual average of nearly 191 million tons of greenhouse gas (GHG) reductions, 59% of the world total. Most of the projects are for wind power, hydropower, waste heat recovery, HCF23 decomposition, and reforestation; there are also a handful of landfill gas projects. Only four China biogas projects were found:

- The French NGO Initiative Développement is building 1,650 household biogas tanks in the Weining and Danzhai Districts of Guizhou Province over the three-year period 2007-2009. The credits (not clear how many) are being sold by Action Carbone for €15.00 each.

- The World Bank has agreed to pay 6.3 million yuan/year for 10 years for the 67,000 tons/year GHG emission reductions at the Minhe biogas project in Shandong. The project is a 20,000 cubic meter digester that processes 180,000 tons of chicken waste to produce 10.95 million cubic meters of biogas and 250,000 tons of fertilizer, and 21.9 million KWh of electricity per year. The World Bank’s Carbon Finance Unit notes that without the carbon credits, the project’s annual revenue would be 7.6 million yuan, but with the credits it is 14.2 million.

- The World Bank also agreed to buy 10 years of certified emission reductions (CERs) from a household biogas project in Enshi Prefecture. This project—part of the World Bank’s Eco-Farming Project—is to provide 33,000 households with digesters ranging from 8 to 15 m3, plus three renovations. The biogas will largely replace coal and is expected to reduce GHG emissions by 58,444 tons CO2 equivalent per year at a total price of 5.74 million yuan. 60% of this money will be given directly to the peasants, presumably to help them pay their share of the costs.

- Finland’s government will pay Beijing Hebayi Ecological Energy Development Company €14.5 million (US$18.26 million) for 1.4 million CERs for the period 2009-2018. The company will install biogas digesters and cookers in 210,000 households in Hunan Province.

Benefits

Since the earliest days of popularization, the Chinese identified 10 benefits of household biogas digesters:

1. Biogas is renewable and saves fossil fuels.

If all the manure and “night soil” (human waste) produced annually in China were converted to make 130 billion m3 of biogas, theoretically it could replace the equivalent of 93 million metric tons of coal (1 metric ton is 2,205 pounds). The actual achievement is more modest, of course. In 2005, the production of biogas was 6.5 billion m3, with an energy content of 135,902 terajoules (TJ=1 trillion joules).

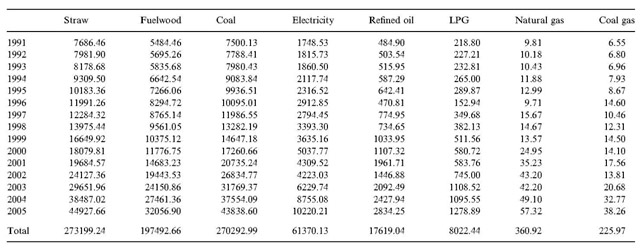

Table 2 gives a national overview of the various fuels substituted by biogas in rural households in the 15-year period 1991-2005. Among fossil fuels, coal is the leader, with 43,838.60 terajoules (TJ) being replaced in 2005 alone. That is about 2.2 million metric tons of coal. The real savings might be six times higher, considering that the efficiency of biogas stoves is 60%, compared to only 10% for traditional stoves.

Table 2. Fuels substituted by biogas for rural livelihood (TJ)

Source: Liu et al. (2008)

The electricity, refined oil, LPG, natural gas, and coal gas replaced amount to 14,429 TJ.

2. Requires less labor than the same amount of energy from conventional sources.

An average household digester requires 30 man-days to build. After that, liquid sludge is removed every two weeks and the sediment is removed once a year. This requires no special skills.

But the factor mentioned most often in this regard is the labor saved for women and children who collect firewood. This saves 1-2 hours per day, or 1-2 days per week. At an opportunity cost of 3.14 yuan/hour (Feng et al. 2009), the benefit amounts to 1,146-2,292 yuan/year for each household.

3. Saves fuelwood and protects forests.

Estimates vary, but one household digester can save about 2 tons of firewood and 0.25 hectare of forest per year.

Table 2 indicates that biogas replaced 32,056.90 TJ of fuelwood in 2005, equivalent to 2.1 million metric tons of wood. With the increased efficiency mentioned above, the amount replaced might be 12.6 million tons.

4. Saves straw and other crop residues for animal fodder and bedding.

As Table 2 shows, straw is the predominant household fuel substituted by biogas. In 2005, 44,927.66 TJ were substituted, which with an energy content of 10-17 GJ per ton amounts to 2.64-4.49 million tons of straw and other crop residues.

5. Reduces expenditures for fuel.

Estimates for fuel expenditure savings from a household-sized biogas digester range from 30 yuan for a household that mostly collects its own firewood to over 1,000 yuan for a household that relies heavily on coal for cooking.

6. Reduces household labor time spent on cooking and housekeeping.

Besides the time saved on gathering fuelwood, the time spent cooking is greatly reduced with biogas. This is not only because of the time spent starting and feeding a fire versus simply turning on the gas valve, but also because of the better heat efficiency. Women interviewed in two separate studies in Shanxi Province reported that cooking a meal takes only ½ hour, compared to over 1 hour with traditional fuels. “I feel like a liberated woman!” said one. Moreover, the time previously spent on cleaning smoke-blackened utensils and ash-covered surfaces can be put to more productive uses as well. According to Ho (n.d.), 80% of women and children in biogas households use their saved time to earn extra income, accounting for as much as 24% of the family’s monthly income.

7. Improves hygienic conditions.

The anaerobic digestion process is very effective at destroying a wide range of pathogens—E. coli, Schistosoma, Shigella, hookworms, dysentery-causing bacilli, spirochetes, etc. This greatly reduces the incidence of water-borne infectious diseases and parasitic infections, as well as related medical expenses. In Mianyang city in Sichuan Province, for example, the number of cases of schistosomiasis decreased by 88% after 1975, when biogas became widely popularized there.

8. Yields a high-quality fertilizer.

Both the liquid slurry and the sedimentary sludge from biogas digesters are rich in nutrients, minerals, and biologically active compounds that form an excellent organic fertilizer. Compared to aerobic fermentation (composting), the anaerobic process reduces nitrogen loss from 50-80% to just 5-12%. It also increases ammonia content by 120% and quick-acting phosphorus by 150%.

An average digester in a warm region can yield 100 kg of sludge twice a year with about 650 ppm N, 40 ppm P, and 9,400 ppm K. This can be used as a soil conditioner or as a substrate for culturing mushrooms or earthworms. The liquid effluent, which is removed more regularly, contains about 550 ppm N, 15 ppm P, and 2,000 ppm K. Using the slurry reduces the need for irrigation water as well as for chemical fertilizers.

Considerable increases in crop yields are consistently reported. For instance, Yongxing District in Sichuan Province applied more than a million tons of digester effluents to its crops, and food production increased by 11% per year. Moreover, the organic produce can be sold at a higher price (as much as 30% higher) than produce fertilized with chemicals.

Biogas effluents are also fed to fish, producing better survival and growth rates as well as a lower incidence of infectious and parasitic diseases compared to raw manure. They can also be fed directly to pigs and chickens, or serve as a growing medium for pondweed which is fed to animals.

9. Enables mechanization of some rural crop processing tasks and local electricity generation.

Biogas contributes to greater yields and efficiency in agriculture when used as a fuel source for farm machinery, irrigation pumps, and threshers. It also supplies the energy needs of small-scale rural industries such as tile making and food processing.

Electricity generation is especially suitable for large livestock operations and industries with organic wastes. For instance, with a little encouragement from General Electric, China’s first chicken manure-biogas plant will use the Beijing Deqingyuan Chicken Farm’s daily output of 220 tons of manure and 170 tons of wastewater to generate 14,600 MWh of electricity as well as heat to promote the fermentation process and heat the chicken farm in the winter.

10. Improves the rural standard of living.

There are a number of ways that biogas increases the income of rural households. Some even report tripling or quadrupling of their incomes. This slows rural-to-urban migration.

- Biogas technicians earn above-average wages.

- Women freed from excessive time spent gathering fuelwood and cooking can pursue income-earning opportunities. Many spend more time growing cash crops such as tobacco and tea.

- In systems that include greenhouses, especially those with pigs or lamps to increase CO2 concentrations, a bounty of fruits and vegetables can be grown. The warmth allows pigs to grow faster, and is conducive to silkworm production.

- The biogas system encourages more animal husbandry at the household level.

To these 10 benefits we must add important reductions in environmental pollution, including air and water pollution.

11. Reduces air pollution.

Besides better hygiene, the most important human health benefit from biogas is a reduction in indoor air pollution. Households that burn coal for cooking have 74% more carbon monoxide, 84% more sulfur dioxide, 27% more carbon dioxide, and 77% more suspended particulates than households that use biogas. Exposure to these high concentrations causes a variety of ailments—pneumonia, chronic obstructive lung disease, cancer and tuberculosis, as well as heart disease and low birth weight. According to Smith (2007), 380,000 premature deaths per year are blamed on indoor smoke from solid fuels in China. It is also bad for the eyes. In an interview with the UN International Fund for Agricultural Development, which helped build 30,000 biogas digesters in China, farmer Liu Chun Xian is quoted as saying, “We used to cook with wood. The smoke made my eyes tear and burn and I always coughed. The children too were often sick and had to go to the clinic, which was expensive. Now that we’re cooking with biogas, things are much better” (IFAD n.d.).

As a result of the fuel substitution in the household, and fewer crop residues being burned in open fields, ambient (outdoor) air quality is improved as well, especially particulate matter and SO2, which causes acid rain.

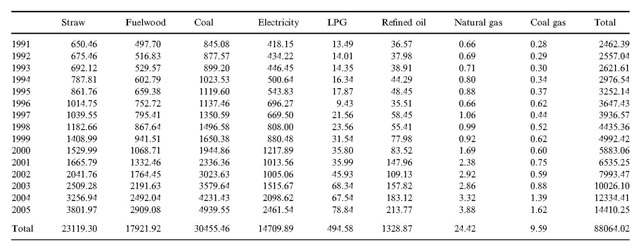

As mentioned above, biogas also reduces greenhouse gas emissions. Table 3 presents an overview of greenhouse gas emissions reductions (in CO2 equivalents) from energy substitutions with biogas for the years 1991 to 2005. The majority (95.67%) is CO2; CH4 accounted for 4.03% and N2O for 0.29%. One gigagram (Gg) is equivalent to 500 metric tons, thus the total 14,410 Gg for 2005 is equivalent to 7.2 million tons greenhouse gas emissions reduction.

Table 3. Greenhouse gas emission reduction by energy substitution (Gg CO2-eq)

Source: Liu et al. (2008)

Besides the energy substitution effect shown in Table 3, Liu et al. (2008) also calculated methane reductions from better manure management with biogas (swine + human manure). The reductions were about 660 Gg CO2-eq in 1991 and 3,000 Gg CO2-eq in 2005. Adding together energy substitution and manure management, but subtracting GHG emitted from burning biogas, they arrived at a sum of 14,000 Gg CO2-eq in 2005, or 7 million metric tons.

12. Reduces water pollution.

Livestock and poultry wastes are precious resources if used properly, but constitute major pollution when discharged into rivers and lakes. Groundwater resources are affected as well. For industrial wastewater, Kangmin and Ho (2006, p. 3) provide the example of a distillery: “The COD (chemical oxygen demand, a measure of pollutant concentration) of wastewater from a distiller often reaches 40 000 mg/litre while aerobic treatment only permits COD below 1 000 mg/litre, which means having to dilute the wastewater 40 times. With anaerobic digestion, 90 percent of the pollutants can be readily removed, thereby greatly reducing pollution to farmland, rivers and lakes.”

EcoTipping Points Analysis

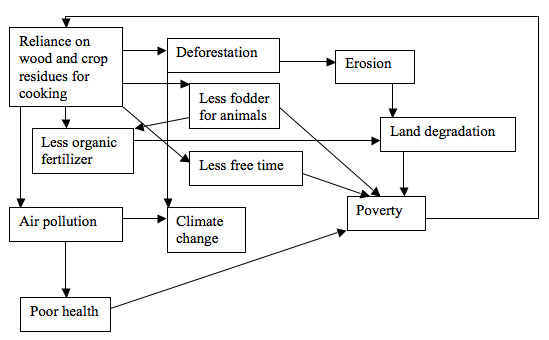

In this case, there is no negative tipping point per se. Biomass has been used for cooking for millennia. This is sustainable until growing demand causes shortages, as is the case in some regions of China. It also has a number of negative side effects, as shown in Figure 8.

Figure 8. Diagram of the effects of cooking with wood and crop residues

The reliance on wood and crop residues for cooking leads to deforestation, which leads to erosion and land degradation. Fewer crop residues returned to the soil means less organic fertilizer, which also causes land degradation (and the need for expensive chemical fertilizers). Burning crop residues means there is less fodder available for livestock, and therefore less livestock and less manure to be used as organic fertilizer. The time spent collecting fuel, and the long cooking times due to inefficiency, means less time available for other pursuits. Air pollution—especially indoor air pollution—leads to poor health. All these effects lead to poverty, which in turn prevents rural households from switching to relatively clean (albeit non-renewable) commercial fuels like kerosene or natural gas for cooking.

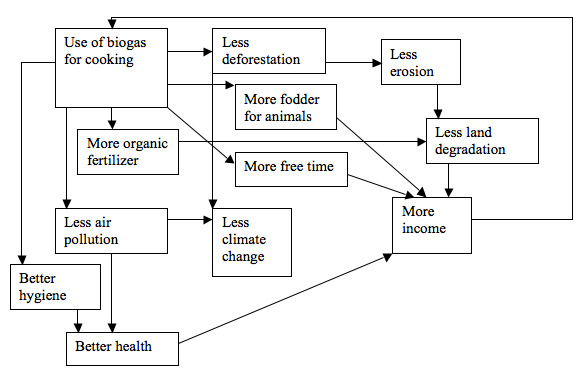

Figure 9 shows the beneficial effects of cooking with biogas—essentially a reversal of the vicious cycle shown in Figure 8, with the added benefit of better hygiene and its associated reduction in disease.

Figure 9. Diagram of the effects of cooking with biogas

In terms of the ingredients we have observed in other case studies, the following was found:

- Outside stimulation and facilitation. Rural households received encouragement to install biogas systems from the national, provincial, and county governments, and more recently from international organizations.

- Strong local democratic institutions and enduring commitment of local leadership. Before 1978, the communes made decisions regarding biogas implementation. Since then, individual households choose to make this investment, but there is still a strong network of extension assistance.

- Co-adaption between social system and ecosystem. Biogas has greatly improved the relationship between humans and their environment. With the use of biogas, the rural quality of life is improved along with the health of the ecosystem.

- “Letting nature do the work.” Anaerobic digestion works wonders in terms of producing a usable fuel and high-quality fertilizer as well.

- Rapid results. A household-scale digester requires only 30 man-days to build. The financial cost is usually recouped in 12-18 months. Benefits such as reduced indoor air pollution and better hygiene are immediately apparent, and high-quality fertilizer is produced within a few months.

- A powerful symbol. Presumably, Chinese biogas propaganda included powerful symbols.

- Overcoming social obstacles. Extensive propaganda and training programs, as well as government subsidies, have helped to overcome technical and financial obstacles. There seems to have been no social opposition to biogas development that needed to be overcome.

- Social and ecological diversity. Diversifying household fuel sources to include biogas allowed families to spend much less time on gathering fuelwood, which led to more diversification of farm crops.

Conclusion

Despite rapid urbanization in China, the number of rural household biogas digesters shows steady growth. The associated benefits make the investment well worthwhile. Larger-scale systems for livestock operations, wastewater treatment plants, and industries show promise in reducing China’s heavy reliance on coal as an energy source.

Ho (n.d.) notes that industrialized countries should also take advantage of biogas: “Paying cash to poor countries not to burn firewood is a measure of desperation for rich countries like the United States …. It would make much better sense for developed countries to cash in on the benefits of biogas themselves, as they also have greater capacity for research and development to optimise the production and use of biogas.”

References

- Action Carbone. n.d. Construction of Biogas Plants in China. Website http://www.actioncarbone.org/en/projet.php?typ=CO2&id=28

- The BioenergySite. 2008. China Fires Up First Chicken Manure-Biogas Plant. Website http://www.thebioenergysite.com/news/1295/china-fires-up-first-chicken-manurebiogas-plant

- Blobaum, Roger. 1980. Biogas production in China. P. 212-216 in Biogas and Alcohol Fuels Production. Proceedings of a Seminar on Biomass Energy for City, Farm, and Industry. Emmaus, PA: The JG Press.

- Chen Ru-Chen. 1981. The Development of Biogas Utilization in China. Natural Resources Forum 5(3), p. 277-282.

- China Economic Net. 2009. Finland to buy CO2 emissions from Chinese biogas project.

- Federated States of Micronesia Public Information Office. 2009. Pilot Biogas Project from China Put to Use. Website http://www.fsmpio.fm/releases/2009/april/04_19_09.html

- Feng, Tingting, Shengkui Cheng, Qingwen Min, and Wei Li. 2009. Productive use of bioenergy for rural household in ecological fragile area, Panam County, Tibet in China: The case of the residential biogas model. Renewable and Sustainable Energy Reviews 13, p. 2070-2078.

- Gan, Lin and Juan Yu. 2008. Bioenergy transition in rural China: Policy options and co-benefits. Energy Policy 36, p. 531-540.

- Ho, Mae-Wan. n.d. Biogas Bonanza for Third World Development.

- Hu Qichun. 2006. The Promotion of Rural Domestic Biogas Plants in P.R. China.

- IFAD (International Fund for Agricultural Development). n.d. China biogas project turns waste into energy. Website http://operations.ifad.org/web/guest/country/voice/tags/china/biogas

- Junfeng, Li. 2007. REEEP: Activities that Support AD Project Development Worldwide. Paper presented at the Methane to Markets Partnership Expo, Beijing, 30 October – 1 November.

- Kangmin, Li and Mae-Wan Ho. 2006. Biogas China. Institute of Science in Society Report. Website http://www.i-sis.org.uk/BiogasChina.php

- Liu Yu, Kuang Yaoqiu, Huang Ningsheng, Wu Zhifeng, and Xu Lianzhong. 2008. Popularizing household-scale biogas digesters for rural sustainable energy development and greenhouse gas mitigation. Renewable Energy 33, p. 2027-2035.

- Lixin, Zhao. 2007. Current Status and its Potential for Large and Middle-sized Biogas Plant in China. Paper presented at the Methane to Markets Partnership Expo, Beijing, 30 October – 1 November.

- Lowry, Cindy. 1980. Biogas Systems as a Competitive Source of Energy for Developing Countries. Paper presented at the Resource Systems Conference, May 3, Honolulu, Hawaii.

- McGarry, Michael G. and Jill Stainforth. 1978. Compost, Fertilizer, and Biogas Production from Human and Farm Wastes in the People’s Republic of China. Ottawa: International Development Research Centre.

- Moulik, T. K. 1985. The Biogas Program in India and China. Ambio 14(4-5), p. 288-292.

- Owens, Gene M. 2007. Analyzing impacts of bioenergy expansion in China using strategic environmental assessment. Management of Environmental Quality 18(4), p. 398-407.

- People’s Daily. 2009a. More rural areas turn to biogas. Website http://english.people.com.cn/90001/90778/90857/90860/6705135.html

- People’s Daily. 2009b. China’s largest biogas CDM project runs smoothly. Website http://english.people.com.cn/90001/90776/90881/6809282.html#

- Smil, Vaclav. 1977. Energy Solution in China. Environment 19(7), p. 27-31.

- Smil, Vaclav. 1982. Chinese biogas program sputters. Soft Energy Notes 5(3), p. 88-90.

- Smith, Kirk R. 2007. Methane Emission Reductions: Opportunities to Promote Health, Development, and Climate. Paper presented at the Methane to Markets Partnership Expo, Beijing, 30 October – 1 November.

- Tianren Trade News. 2009a. Over 30.5 million Chinese household are using biogas for cooking. Website http://www.tianren.com/en/news.asp?id=180

- Tianren Trade News. 2009b. “Three extension” to enlarge the using of biogas. Website http://www.tianren.com/en/news.asp?id=170

- Tianren Trade News. 2009c. China 1st CDM program of Household Biogas Plant is successfully registered. Website http://www.tianren.com/en/news.asp?id=94

- Tu Jiapao and Lu Chengxian. 1984. Rural Methane Resources and Their Utilization. Chapter 5 in Rural Energy Planning in China and Other Developing Countries of Asia, edited by Deepak Bajracharya. Honolulu: East-West Center.

- USAID. 2009. China – Nature Conservancy alternative energy project. Indoor Air Pollution (IAP) Update, July 6. Website http://iapnews.wordpress.com/2009/07/06/china-nature-conservancy-alternative-energy-project

- van Buren, E. Ariane. 1980. Biogas Beyond China: first international training program for developing countries. Ambio 9(1), p. 10-15.

- Wang, Gehua. 2004. ‘Four in one’ model and the development of household biogas in northern China. International Journal of Global Energy Issues 21(1/2), p. 110-118.

- Wright, Martin. 2006. All you need is spirituality … and slurry. Green Futures July/August, p. 4-5. Website http://www.forumforthefuture.org/greenfutures/articles/602538

- Yang, H.S. 2006. Resource management, soil fertility and sustainable crop production: Experiences of China. Agriculture, Ecosystems and Environment 116, p. 27-33.

- Zhang Pei-dong, Jia Guomei, and Wang Gang. 2007. Contribution to emission reduction of CO2 and SO2 by household biogas construction in rural China. Renewable and Sustainable Energy Reviews 11, p. 1903-1912.